About QED XT25 Speaker Cable

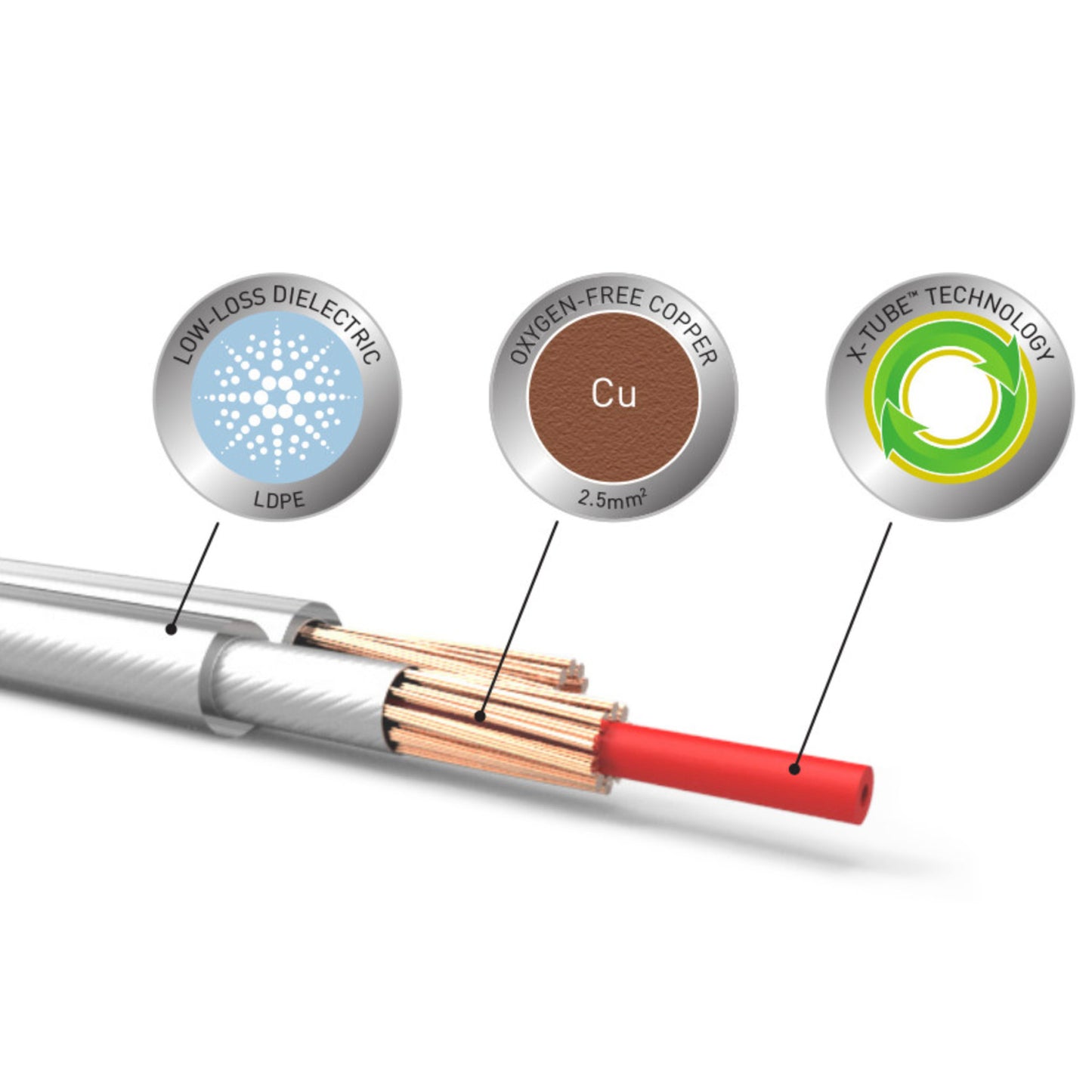

The QED Reference XT25 speaker cable might just be the sweet spot in QED's cable range. It uses QED's LDPE low loss dielectric along with pure oxygen free copper and the company's proprietary X-Tube technology. This results in a cable with sensational levels of clarity and detail yet which is surprisingly affordable. This kind of transparency at anywhere near this price is truly difficult for rivals to match.

All QED cables are designed using the top down principle. XT25 represents the core musical performance trickled down from QED's money-no-object Supremus cable in a more affordable package. QED has won more What Hi-fi? Awards than any other single brand and with XT25 this heritage is delivered at a sensible price. Unlike most other manufacturers, QED offer an unlimited lifetime guarantee which means that if your cable ever fails to deliver to its full potential during its lifetime QED will replace it free of charge.

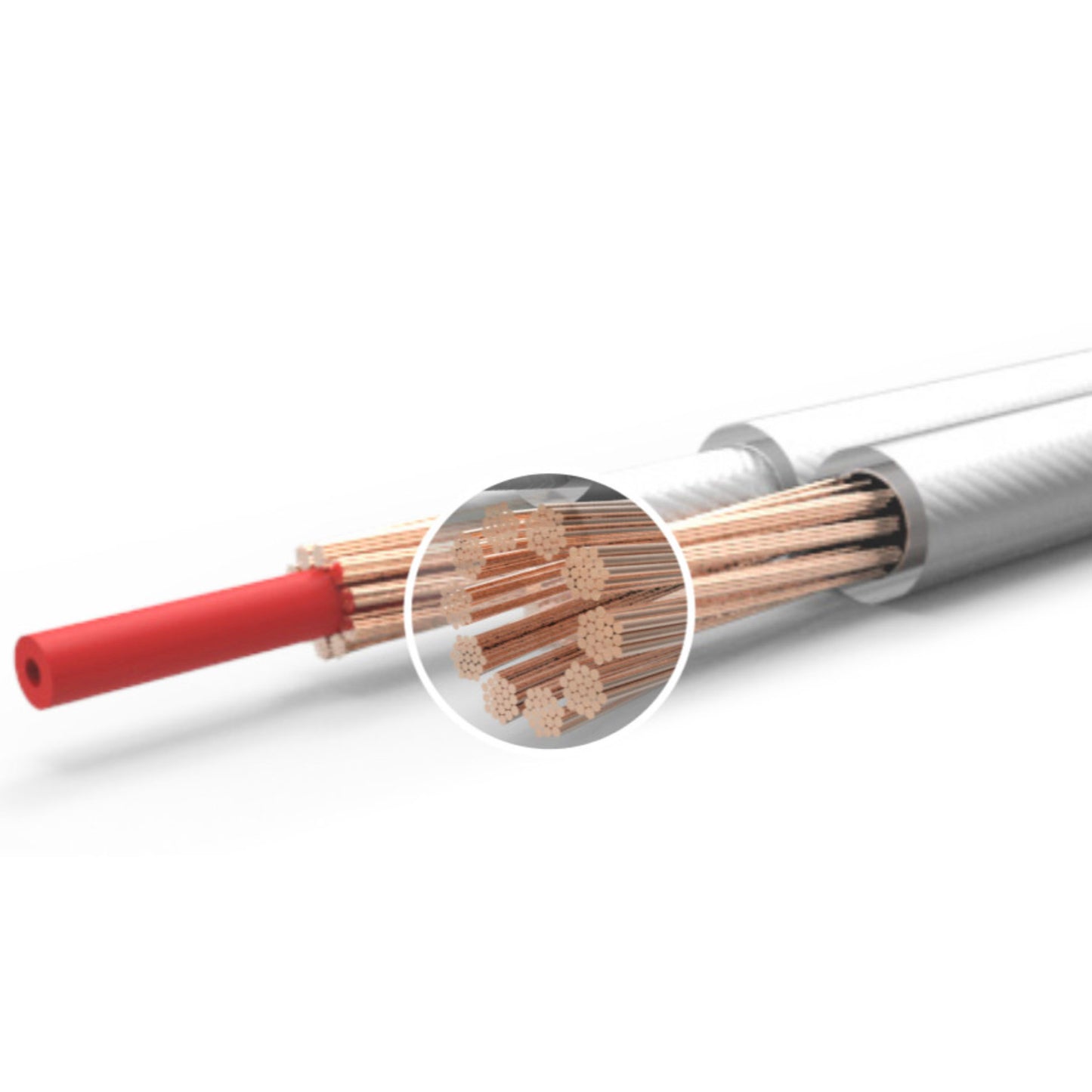

X-Tube Technology: In loudspeaker cables high pitched sounds are forced to travel towards the outside of the conductor and so are able to use less and less of the available cross-sectional area as the pitch increases. This is called the "Skin Effect". It means that for high frequencies the resistance of the cable appears to be much higher than it does for lower pitched sounds. Eddy currents in one conductor can affect the current flowing in an adjacent conductor so that currents flowing in the same direction move away from each other. This "Proximity Effect" also increases resistance as frequency increases. These phenomena have a detrimental effect on the fidelity of the sound you hear. The XT25 variation of QED X-Tube solves these problems by creating a hollow tubular conductor geometry out of individual conductor bunches through which each frequency can pass with equal ease when compared to traditional solid or stranded conductors.

Low-Loss Dielectric: Music signals in a loudspeaker cable move back and forth many times every second. The insulating material used to separate the send and return conductors from each other (the dielectric) has to be charged and discharged every time. Not all of the energy stored in the dielectric during each charge cycle is completely returned during each discharge cycle which has a detrimental effect on the fidelity of the sound you hear. Like its predecessors, XT25 uses a specially formulated low-density polyethylene (LDPE) dielectric. QED research has shown that low capacitance cables are generally preferred in listening tests over high capacitance counterparts and this is usually because low-loss dielectrics have been utilised. The use of LDPE and careful control of conductor spacing results in a cable with a very low capacitance per meter and a dissipation factor (loss tangent) of 0.0001 at 10 kHz.

99.999% Oxygen-Free Copper: Speaker cables need to have a large current carrying capacity. If the electrical resistance of the cable is too large, part of the music signal will be lost, causing a detrimental effect on the fidelity of the sound you hear. To stop this from happening QED make the resistance of their speaker cables as small as possible. They do this by using the largest practical cross-sectional area of copper within the size constraints of each cable. In order to squeeze the last drop of performance from the conductors they make sure that there are no impurities in the copper which would defeat the object of making them so large. That's why QED use 99.999% oxygen-free copper exclusively.

What is Airloc?

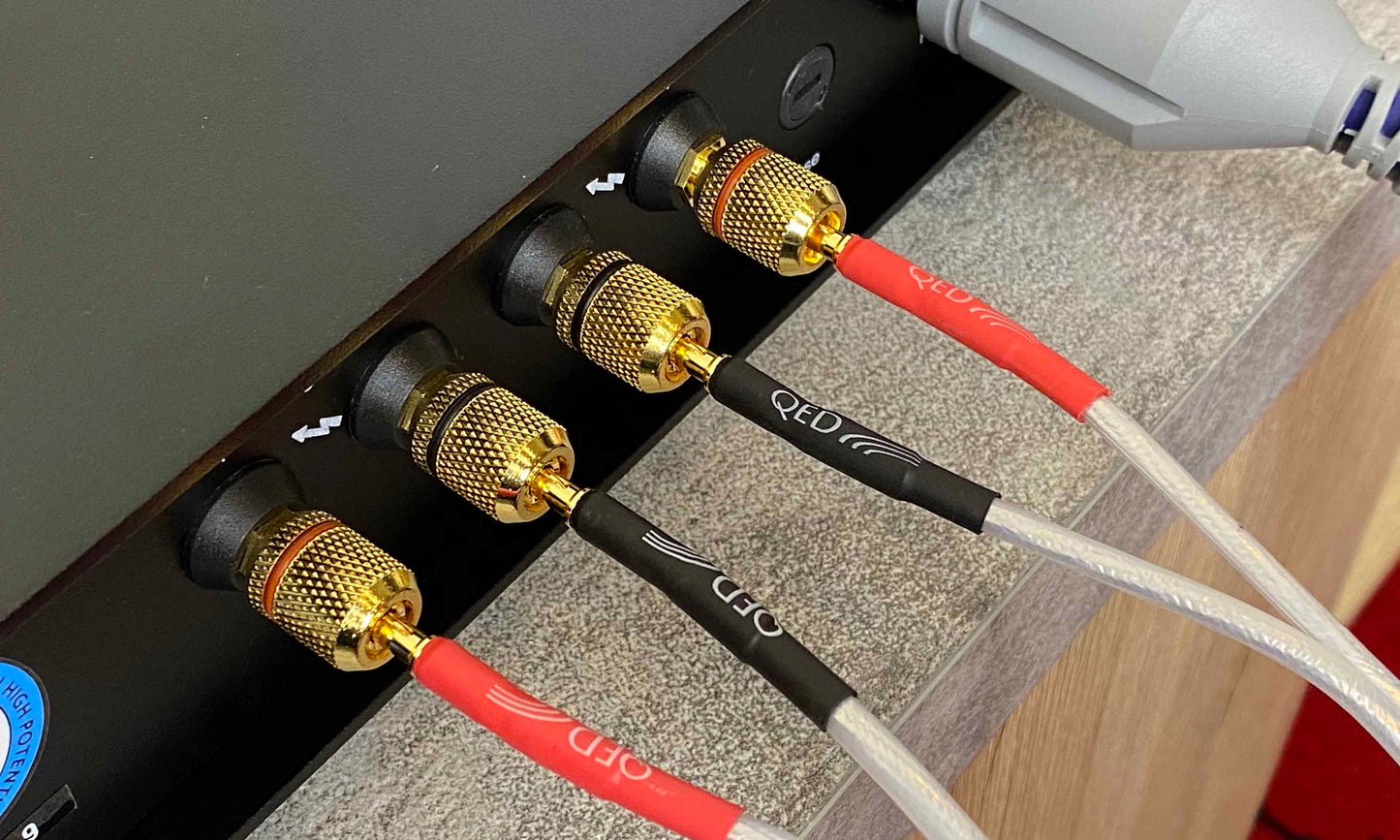

Airloc is a form of cold weld system that permanently attaches QED Forté banana plugs and spades to the entire range of QED and many other speaker cables. One of the main reasons for choosing a QED speaker cable is the superior d.c. resistance characteristics offered by their exclusive use of 99.999% OFC or oxygen free copper conductors. It isn't the smart thing to then go ruin all this attention to detail by neglecting the most vulnerable area of the speaker cable chain - that of the physical interface between cable and amplifier or speaker terminals. Since the mid 1970's there has been more co-operation between manufacturer's to allow for easier installation of good speaker cables and most products allow for use of both banana plugs and spade terminals. No, you don't have to use them, but they definitely have advantages over bare wire alone. Why?

Seen under a microscope the surface of a typical copper strand is very rough and so using normal screw type terminals - such as found on binding posts or cheap banana plugs - electrical contact is only made in a relatively small number of places. Add to this a layer of oxidation - which is inevitable if copper is exposed to the air for even a short time - and the combined resistance of the cable and its termination can creep back up to levels present in a more inferior cable.

By using a cold weld crimp type termination, QED Airloc Forté plugs squash the conductors and plug together to increase contact area and reduce resistance. By the time the full pressure has been applied the resistance of the joint has reached a minimum value.

Now, because all the air has been removed from the joint there will be no oxidisation of the contact surfaces so the low resistance will remain for the lifetime of the cable. During the cold weld process the cable and plug become one solid piece of metal. Since the copper contact has been effectively removed from the resistance equation we can concentrate on the plug to terminal resistance.

What are QED Forté Plugs?

The plugs themselves are made of solid brass which has roughly twice the resistivity of copper. For this reason the QED Forté 4mm banana plug was devised so that its cross-sectional area would be at least double that of the cable to which it was connected effectively cancelling out the extra resistance of the plug material. QED then plates the connector with high purity gold which has a resistivity almost as low as copper but more importantly does not oxidise in air. The relatively smooth gold surfaces provide a larger contact area than the uneven copper strands in the cable and because the gold will never oxidise the contact surface remains clean and low resistance for life.

The QED Forté plug pin section is designed to maximise contact area throughout the wide tolerance range encountered in 4mm amplifier and speaker sockets. Here some are quite tight whereas others are loose, so the spring loaded Forte blade is designed to fit into smaller and larger sockets with equal insertion force. This means that the contact area is maximised and the connection remains uniformly tight. QED Forté with Airloc technology is top-notch and delivers guaranteed low resistance and strength - for life.

The History Of QED

In 1973 Bob Abraham and Ian Vine founded QED Audio Products and changed the way people think about hi-fi cables. By the time QED 79 strand was launched in 1978, it wasn't considered' just another speaker cable' but a serious hi-fi component.

During 1994 QED conducted the most extensive ever scientific investigation into the effects of speaker cable on hi-fi system performance. Read the results in "The Genesis Report". Hear the results whenever you listen to your favourite music using QED cables.

QED's reputation for innovation and technical excellence is known throughout the world. The latest computer-aided design techniques allow their research and development team to keep pace with technological advances and deliver products that achieve the highest levels of performance and reliability. This is why QED speaker cables are recommended by so many of the world's leading manufacturers of hi-fi and home theatre equipment.

QED is Europe's number one award winning connectivity brand and has won more prestigious cable awards from 'What Hi-Fi? Sound & Vision' magazine than any other brand. - QED - The Sound Of Science

In The News

We loved the more expensive XT40 for precisely the same characteristics shown by the XT25 – and that's the mark of a manufacturer that knows its identity. If you don't want to meet the cost of the former, this is a cable offering the same family sound for a tighter budget, and it won't leave you longing for the upgrade. We know QED for sensational levels of clarity and detail, and, even at this lower price, it doesn't disappoint. This kind of transparency is difficult for rivals to match. What Hi-Fi? 5 Star Review

Our Take ON QED XT25 Speaker Cable

QED XT25 is the sort of speaker cable that can really open up a system. If you have a system that is already bright and detailed then this may not be the cable for you. But if you have a balanced, natural sounding system and are looking to eke out that extra level of clarity while keeping a balanced sound signature then the XT25 could absolutely do the trick. Its level of transparency is sure to win lots of fans and when its affordable price is taken into consideration it starts to look like something of a bargain. We cannot recommend this cable highly enough. Buy with confidence.

Main Features & Specifications

- Cross-Sectional Area: 25 mm2

- Wire Gauge: 14 AWG

- Jacket Outside Diameter: 3.96 mm

- Loop Resistance: 13.4 mΩ/m

- Capacitance: 35.0 pF/m

- Loop Inductance: 0.52 μH/m

- Dissipation Factor: @ 10 kHz 0.0001

- Conductors: 10 X 19/0.13 mm

- Insulation: LDPE Jacket With 100% Coverage of Aluminium Mylar tape wrap

- Available Lengths: 2, 3 & 5 Metres

- Plugs: QED Airloc Forté Banana Plugs

- Manufacturer's Warranty: Lifetime

Note: Features & Specifications Subject To Change Without Notice. E&OE